500-750 kg per hour

Designed for forming of seamless, burrfree, non filled & filled candies, hard and chew candy

thoughtfully built

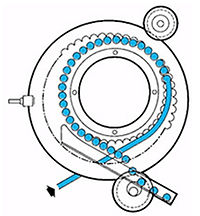

The UNIPLAST Candy Forming has been designed for the continuous production of seamless sweets, using a UNIPLAST type rotary die arrangement. Solid and centre-filled products of Hard candies, Toffee Éclair, Chewy candies have all been successfully manufactured

A typical production line comprises of the Centre filler, Batch Former, Five Stage Rope sizer, UNIPLAST Candy Forming Machine and cooling conveyor.

The UNIPLAST Candy Forming Machine is at the heart of the candy processing line and has therefore been designed with strength and durability as its main assets. The machine has a number of features, which make it an ideal choice for candy manufacturers.

-

Die rotation speed is variable by AC Drive

-

The speed of the in feed rollers can be varied relative to the speed of the die, which is particularly useful for difficult products like chewy candy

-

The main drive is through timing belts to reduce noise level and moving parts

-

Spreader conveyor motor is independent and adjustable

-

Scrap tray under the die with outlet for connection to a dust extraction unit

-

Spring loaded one piece pressure cam with cam rollers.

-

Automatic lubrication to cams and bearings

Output

A maximum of 60 to 80 die revolutions per minute can be achieved.